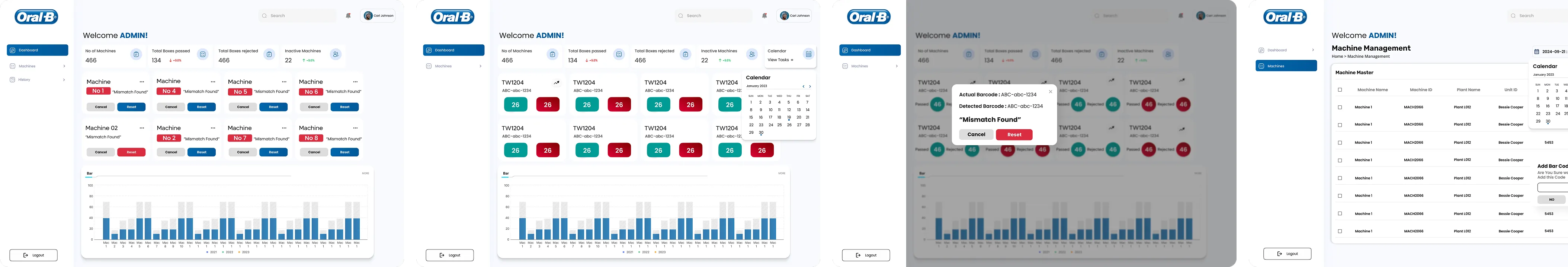

Oral-B Project

An AI-powered quality assurance system that uses barcode validation and OCR-based label checking to ensure correct material placement. It prevents packaging errors, improves shipment accuracy, and enhances overall delivery quality.

Deployed across high-volume logistics and manufacturing environments, this Edge AI solution delivers real-time verification without cloud dependency.

Problem

Incorrect placement of materials into wrong boxes during packing. Label mismatches causing quality issues and shipment errors. Manual checking is slow, inconsistent, and prone to human error. Delivery quality gets affected, harming brand consistency and customer satisfaction. High-volume industries struggle to maintain accuracy in real time.

Solution

AI-powered barcode scanning ensures each item is placed in the correct box. OCR verifies labels for correctness, clarity, and compliance. Real-time Edge AI validation prevents packing errors instantly. Cameras detect mismatched materials before dispatch. System enhances accuracy, ensures consistency, and reduces delivery issues.

Challenges & Results

Challenge

High error rates, slow manual verification, inconsistent quality control

Solution

Fast conveyors, poor lighting, label variations, real-time processing needs

Result

97% accuracy, 99% uptime, 500+ errors prevented in pilot phase

Key Features

What Makes This System Revolutionary

Edge AI Cameras

High-speed processing without cloud dependency

AI Barcode Verification

Confirms correct material placement instantly

OCR Label Checking

Ensures label accuracy, readability & compliance

Real-Time Validation

Detects mismatches during packing process

Instant Alerts

Notifies staff immediately for correction

Seamless Integration

Works with existing ERP & conveyor systems

How the System Works

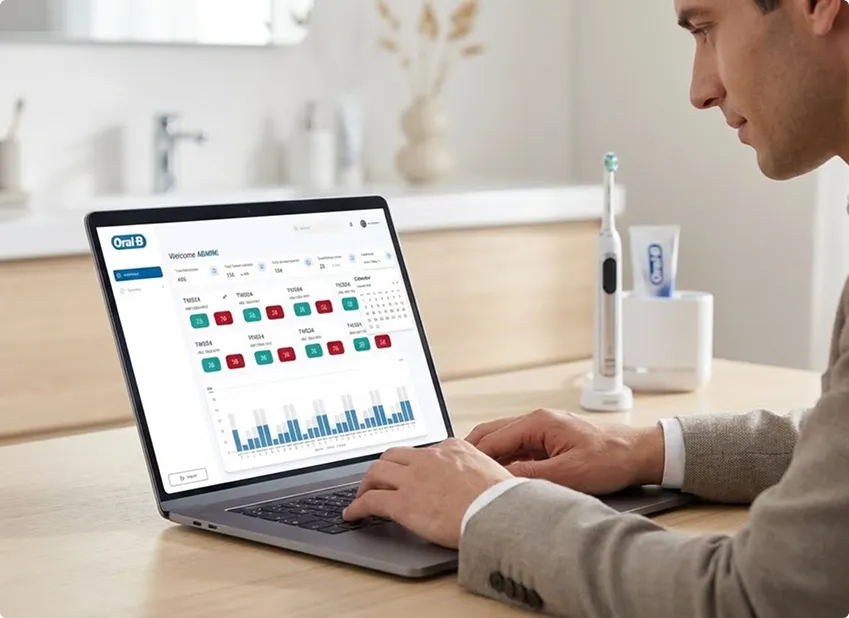

Client Testimonial

"The AI quality assurance system has transformed our packing accuracy. We went from multiple daily errors to near-perfect shipments. The real-time detection and instant alerts have saved us countless hours and prevented costly mistakes."

— Oral-B team