BrakePad AI

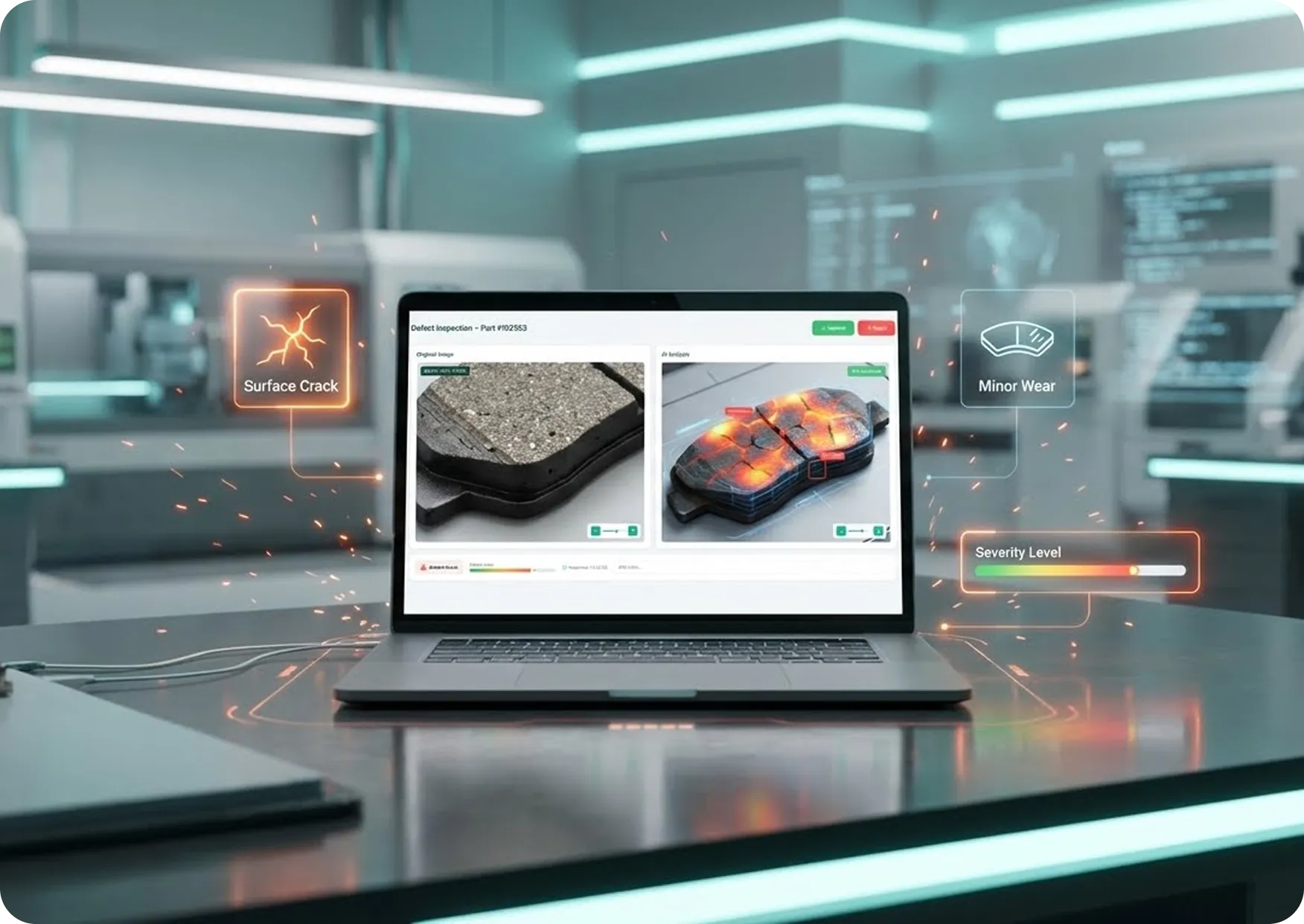

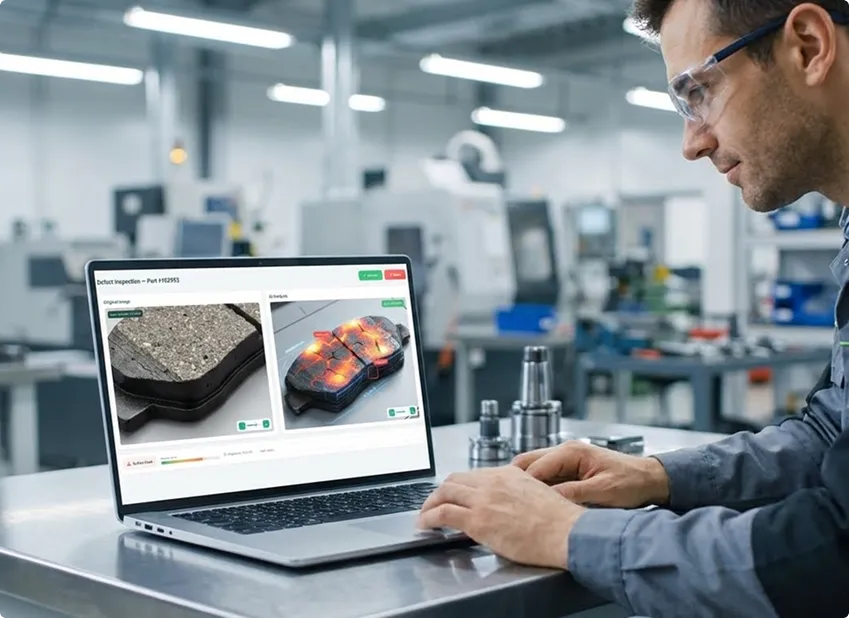

BrakePad AI is an AI-powered brake-pad inspection solution that automates defect detection, ensuring accurate, fast, and consistent quality checks using computer vision.

Problem

Manual brake pad inspection is slow, inconsistent, and prone to human error — resulting in undetected cracks, misalignment, uneven wear, safety risks, and increased manufacturing costs.

Solution

BrakePad AI delivers automated AI defect detection, thickness & consistency verification, real-time alerts, and a comprehensive QC dashboard — ensuring faulty brake pads never reach production.

Challenges

Challenge

Customers struggle to find trustworthy organic products and understand their benefits.

Solution

Educating users, managing higher product costs, and competing in a crowded market.

Result

By focusing on quality, clear communication, and community engagement, Bubble Organic builds trust, loyalty, and long-term customer retention.

Key Features

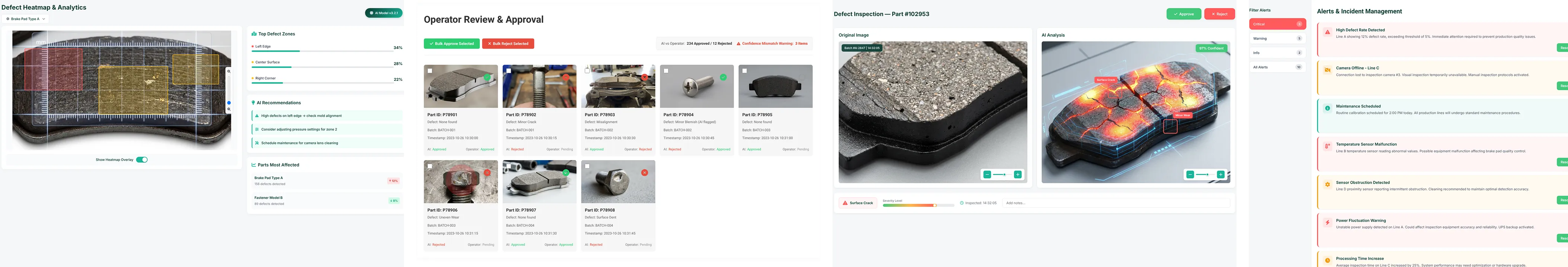

What Makes BrakePad AI Stand Out

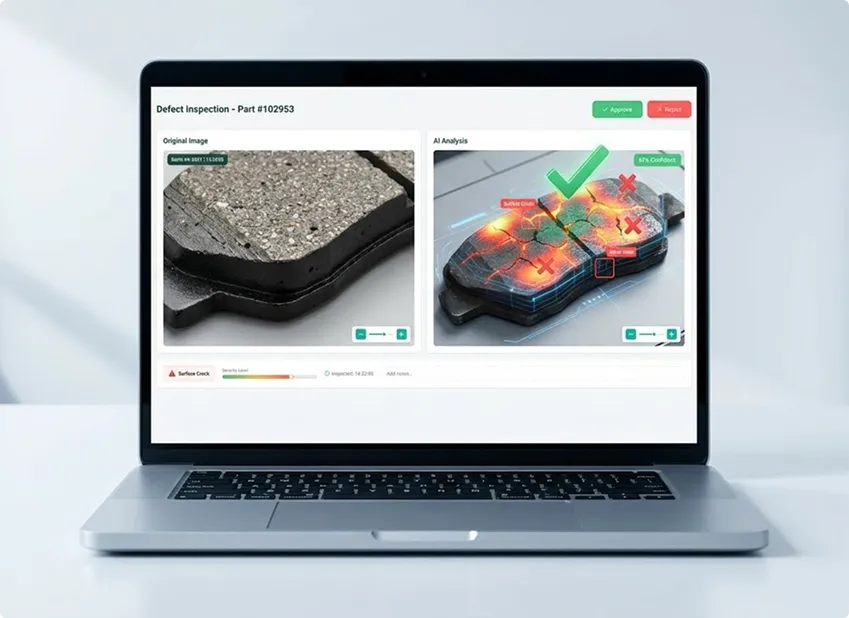

AI Defect Detection

Detects cracks, uneven wear, and misalignment instantly

Thickness & Consistency Check

Ensures proper thickness and material uniformity

Real-Time Alerts

Instant notifications on any defect detected

High-Speed Scanning

Designed for fast-moving production lines

QC Dashboard & Reports

Track performance, trends, and analytics

How the System Works

Client Testimonial

“The AI brake pad inspection system has revolutionized our quality control process. Detection accuracy is outstanding, false rejects are almost zero, and our inspectors now focus on higher-value tasks. A game-changer for automotive safety and efficiency.”

- Leading Brake Pad Manufacturer